A woven label is a type of tag used to mark various information on textiles or clothing. Typically made using weaving techniques, it is a flat fabric label that usually features information such as the company logo, product name, size, and composition. Woven labels are known for being waterproof, durable, vibrant in color, soft to the touch, and easy to insert into sewn products. Common materials used to create woven labels include polyester fiber, cotton thread, and nylon silk. Types of woven labels include black and white woven labels, colored woven labels, heat-melted woven labels, and hang tags, among others. Woven labels are used for brand promotion, product identification, and size recognition, among other purposes, making them an important aspect of the textile and clothing industry.

The manufacturing process of woven labels generally involves the following steps:

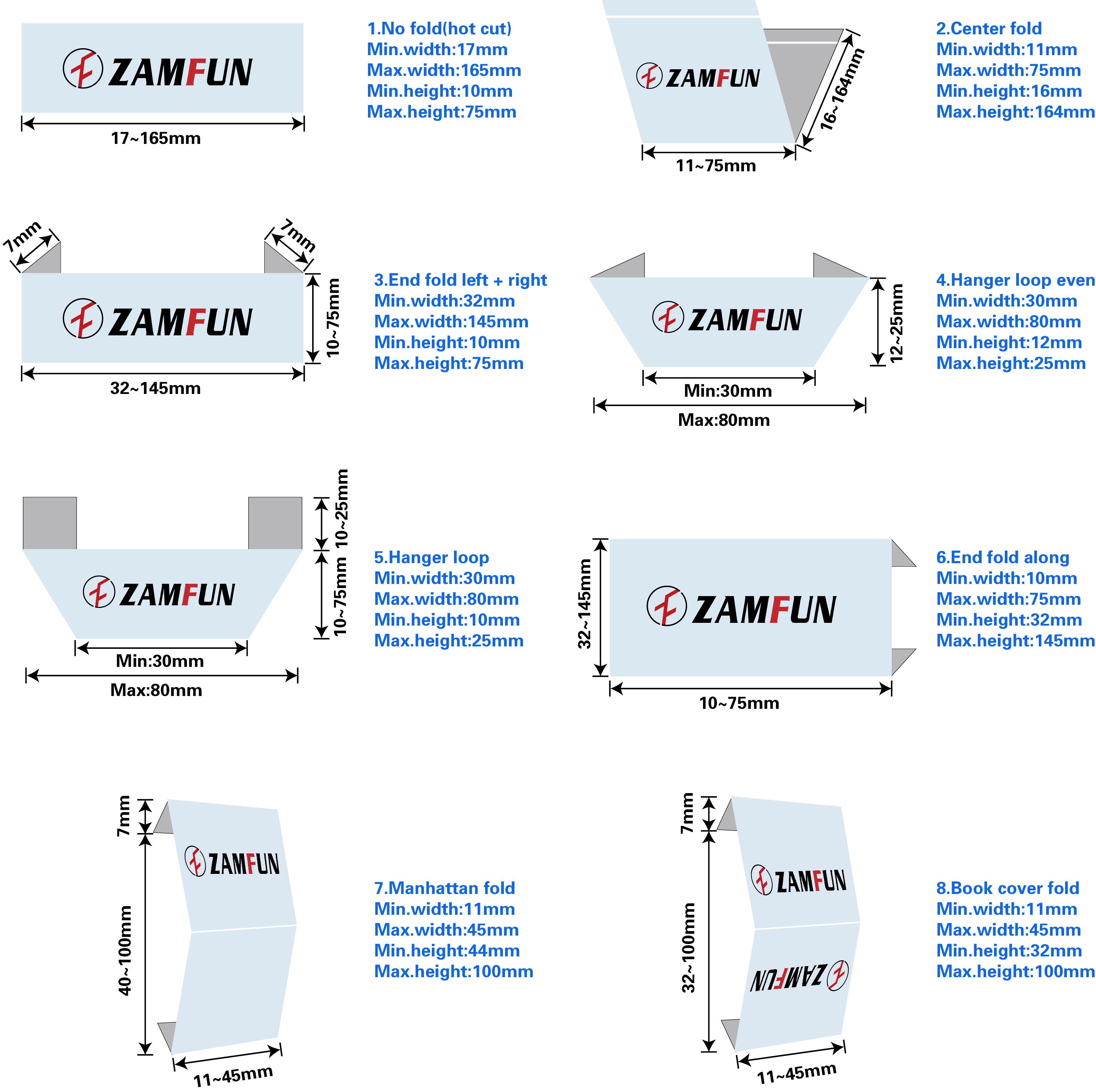

1. Design: Before creating woven labels, it is necessary to design them, including designing the logo, text, size, and other information.

2. Drafting: Import the designed pattern into computer graphics software for adjustment and optimization to meet the requirements of the woven label manufacturing process.

3. Weaving: Weave the designed patterns and text into a fabric label using a weaving machine. Different yarns and weaving methods can be used according to the specific requirements.

4. Processing: After weaving is completed, the label needs to be post-processed to prepare for the next step. This may include hot or cold cutting, hot or cold trimming, etc.

5. Finishing: Sort, stack, pack, and label the processed woven labels to make them into finished products.

6. Sewing: Sew the finished woven labels onto textiles or clothing according to the requirements. Pay attention to the bonding position, flatness, and bonding firmness during the sewing process.

Each step of the above process requires attention to detail to ensure the quality and performance of the woven labels. High-quality raw materials, careful design of patterns, standardized production equipment, and production process control are also important considerations to guarantee high-quality woven label products.

To order customized woven labels, follow these steps:

1. Design: Design a pattern that meets your requirements, such as a brand name or a product name. Usually, vector graphics are used for design, and online design platforms can also be used.

2. Select materials and styles: Choose suitable materials and styles for your needs and usage scenarios, such as soft polyester, nylon, or cotton woven labels.

3. Select a weaving company: Choose a professional weaving company like us that has the specialized techniques and equipment needed to create woven labels that meet your requirements.

4. Submit an order: Inform us of details about your pattern and weaving preferences so that we can produce the customized woven labels for you.

5. Confirm samples: Wait for us to produce a few samples and confirm whether they meet your requirements. Once we have your approval, we will proceed to

Post time: Jun-30-2023